Complete Mechanical Pre Treatment Stations

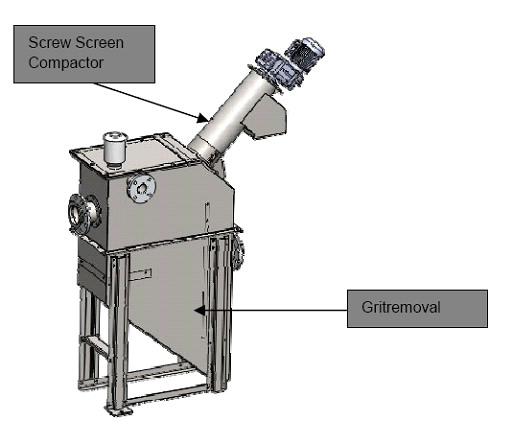

WAU2 : Screen and Grit

WAU3 : Screen, Grit and Grease

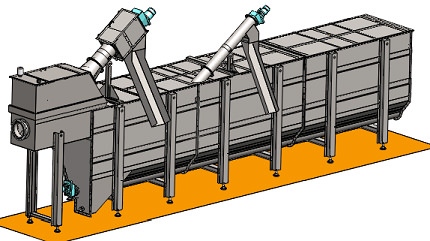

The WAU is an answer to the high civil works costs and large footpoint required execute complete pre-treatment systems in concreate (screening channel, sedimentation tanks and hoppers FOG removal). The WAU system is a state-of-the-art combined pre-treatment system designed to optimally perfrom all the efflument pre-treatment funcation, Screening - Grit removal - FOG removal, in a single steel machine.

The WAU range consists of the FLUITECO WAU 2 (for screening and grit removal) and the WAU 3 (for screening, grit removal and FOG removal).

The WAU is generally supplied with the CFC Screw screen, but in special exection it is also possible to provide it with the GTR auger rotating drum screen, the SSW step screen, the SMC sub-vertical bar screen, or the SMC-PH perforted plate and brush screen.

Principle of operation

The effluent enters into the WAU system, when it is screened by a CFC screw-screen, other screening systems are available as per above. The waste water, after being screened enters inside the sedimentation hopper (with floatation in the case of WAU3). The sand settles to the bottom of the hopper where a shaftless horizontal conveyor, installed along the bottom of the hopper, conveys the sand to the sand extraction area. An inclined sand extraction screw conveyor transports the sandout of the sand extraction area for discharge. This inclined conveyor can be supplied shafted or shaftless in function of the effluent type.

The WAU3'S sedimentation hopper features and FOG removal compartment equipped with air diffusers to make grease and oily substance float to the effluent suface. An FOG scraper, installed on top of this compartment, conveys the FOG towards the tank FOG outlet.

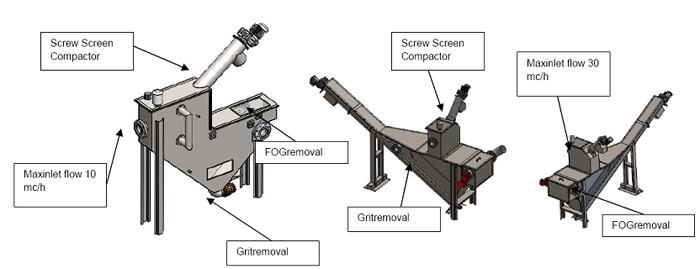

Series 10 and series 30 – Complete Pre Treatment Stations Untill 30 mc/h

Combined pre-treatment station series 10 and 30 are specifically designed to treat flowup to 30m3/h. Theses solutions feature the same robustness and remarkable maintenance simplicity charachteristic of Fluiteco equipment. The performance quality remains uncharged: screenings capture ratioof 70% grit removal efficiency upto 90% for grain size> microns, andan FOG removal efficiency of no less than 85%.

| TYPE | INLET FLOW | HOPPER CAPACITY (m3) | GRIT REMOVAL CAPACITY (m3/h) | |

| m3/h | l/s | |||

| SERIES 10 | 10 | 2,7 | 0.37 | 0.4 |

| SERIES 10 | 30 | 8,3 | 0.7 | 0.7 |

MCB: Complete pre Treatment station small communities

The MBC are combin edpre-treatment unitsdor flows up to 10m3/h. These solutions feature the same robustness and remarkable maintenance simplicity charateristic of FLUITECO equipment. The performance quality remains unchanged : screenings capture ratioof 70%, grit removal effciency upto 90% for grain size> 200 microns, and an FOG removal efficiency of no less than 85%. The MBC is idealpre-treatment solution for small communities such as camping frounds, small urban areas, shopping areas, shopping malls etc....