Grit Separation and Washing

VXGR: Vortex Grit Separtor

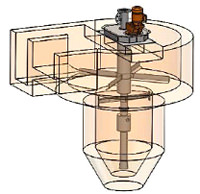

The grit removal system (Vortex) VXGR consists

essentially of a group of mixing blades with adjustable inclination that rotate to create a vortex that promotes the grit sedimentation (even extremely fin grain grain sizes, up to 100 microns). Settled grit is extracted by a pneumatic (air-lift), or by a grit pump positioned outside of the hopper. Vortex VXGR oil and grease.

The grit removal system (Vortex) VXGR consists

essentially of a group of mixing blades with adjustable inclination that rotate to create a vortex that promotes the grit sedimentation (even extremely fin grain grain sizes, up to 100 microns). Settled grit is extracted by a pneumatic (air-lift), or by a grit pump positioned outside of the hopper. Vortex VXGR oil and grease.

Generally this equipmentis introducedin aconcrete tank, but alternatively you can request asteel tank.

| Inlet Flow mc/h | Hopper volume mc | |

| VXGR20 | 430 | 3 |

| VXGR25 | 760 | 5 |

| VXGR30 | 1220 | 8,5 |

| VXGR35 | 1870 | 13 |

| VXGR40 | 3160 | 20 |

| VXGR50 | 5000 | 34 |

| VXGR25 | 8300 | 55 |

The standard air-lift sand extraction system can be substituted with a sand extraction extraction pump. On this last case the air-lift, including the extraction pipe deleted and replaced with a suction pipe of the water/ sand, connected to a pump suitably designed with abrasion resitant.

CDS: Grit Classifier with shaftless Spiral

The Grit Classifier is used for the separation of grit from water. It is composed of as edimentation hopper and a solids extraction screw. The screw is normally shaftless, but a shafted version is also available.

The Screw is normally connected connected directly to the motor.

Operation

The water enters in the hopper and the grit settle to the bottom, to then be extracted by the screw conveyvor. The screw rotatio is low-speed to avoid turbulence and increase process efficiency.

The trough of the extraction screw is protected by a wear-resistant coating HDPE or stainless steel bars.

| Type | Liquid Flowrate(m3/h) | Hopper Capacity (m3) | Sand Removing Capacity (m3/h) |

| CDS 20 | 20 | 0.4 | 0.25 |

| CDS 25 | 30 | 0.9 | 0.4 |

| CDS 60 | 60 | 1.5 | 0.4 |

| CDS 80 | 80 | 2 | 0.4 |

| CDS 100 | 100 | 3 | 0.4 |

Description:

The CDL grit washer is to simultaneously wash and separate the grit contained in wasterwater. It is composed of aconcial sedimentation hopper decantation equipped with acentral stirrer, and shafted grit extraction screw.

The Screw is normally connected directly to the motorviaa flanged shaft. The hopper bottom is equipped with a grit-washing system that introdices clean water in counter-current to remove organic substances in the grit to be reused in the cement/Concrete industrial processing

| Type | WastWater Flowrate | Hopper Capacity (m3) | Sand Removing Capacity (m3/h) | |

| (m3/h) | l/s | |||

| CDS 30 | 30 | 8 | 0.65 | 0.4 |

| CDS 60 | 60 | 16 | 0.9 | 0.4 |

| CDS 90 | 90 | 25 | 1.5 | 0.4 |