UTB Envirotec Zrt - Hungary

I. Continuous flow SBR process incorporating the patented "Feed forward" cycle

The Cyclator Process is a unique variation of the Sequential Batch Reactor (SBR) technology, which incorporates all the advantages of this simple and robust technology while addressing its weaknesses in a very innovative way.

One of the biggest disadvantages SBRs face is the requirement of equalization basins or requirements for multiple reactors. In addition, the diurnal variations in wastewater streams may render multiple basins unevenly loaded.

The Cyclator process is a cyclic/sequential process which achieves very high levels of biological nutrient removal in single or multiple reactors while accepting continuous influent.

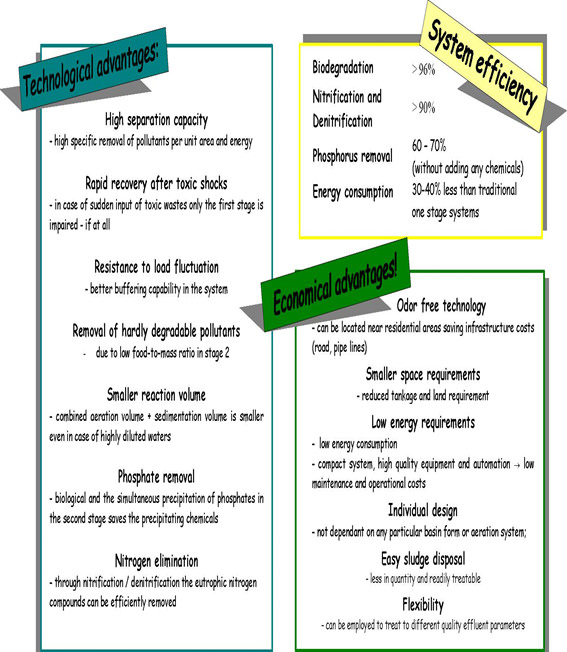

Our unique variation of this cyclic process offers the following features:

A baffle wall (non-hydrostatic) separates the reactor into two zones : selector and reactor

Although SBRs are batch processes, in the cyclator system, the influent flows continuously into the selector zone (even during settle/decant periods)

The reactor accomplishes full nitrification, denitrification and biological phosphorous uptake.

The selector zone limits the growth of filamentous bacteria thereby creating a sludge with a low SVI value

A state-of-the-art decanter controls withdrawal of effluent in a flow proportional manner

A highly advanced oxygen control system ensures minimum energy consumption while guaranteeing highest standards of effluent quality

High quality fine bubble membrane diffusers transfer oxygen efficiently

II. UTB Process Attisholz (2AB) Biological Wastewater Treatment Technology

Nature has the capacity to deal with most of the waste products generated by humans. Virtually all of the organisms working to degrade these organic compounds occur naturally. However, for economic reasons their activity is controlled by construction and operation of special reactors.

The UTB 2AB biological wastewater treatment technology harnesses and optimizes the natural process of microbial degradation in reactors to achieve waste destruction biologically

What it is

The UTB 2AB biological wastewater treatment technology is a two stage activated sludge process. Two different stages, each with their own aeration and clarification and distinct operation parameters, treat the wastewater.

The process was specially developed to address the following core problems:

Removing difficult to degrade wastes from both industrial and domestic waste-waters

Achieving nitrification/denitrification and P elimination -handling extreme load variations.

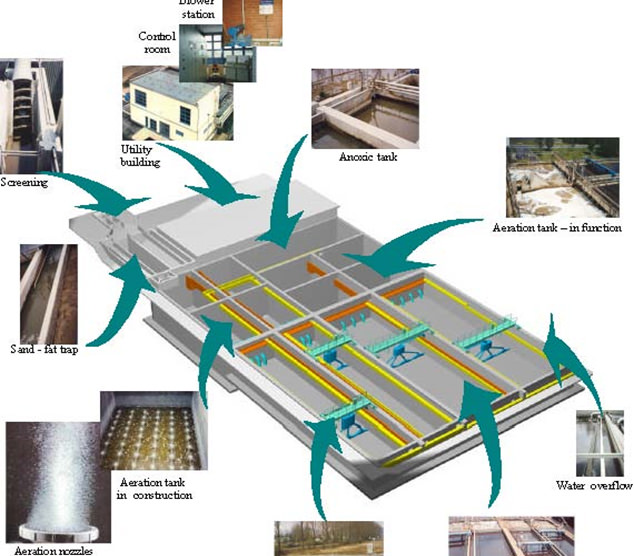

System and components:

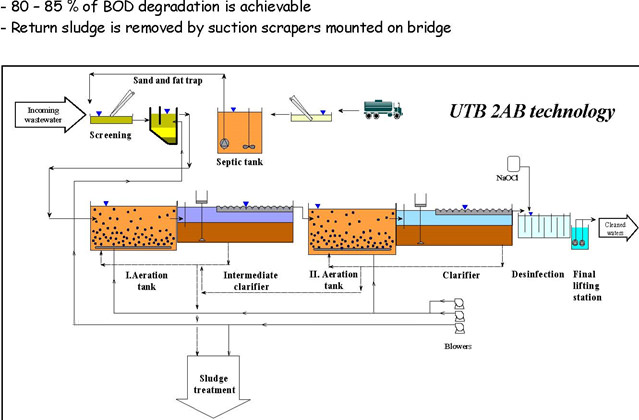

Process flow diagram

Process flow diagram

1. First stage

(aeration tank and intermediate clarifier)

Dissolved oxygen is kept low, Sludge age is low

Organic load is high and removal by bio-sorption and microbial degradation

2. Second stage

(aeration tank and final clarifier)

Dissolved oxygen is maintained high, Sludge age is high, Organic load is low, operation similar to extended aeration, Removes the more difficult to degrade organic matter

Phosphorous removal

Biologically by linking an anaerobic zone in first stage and also simultaneously occurs

Nitrogen removal

Denitirification can be achieved by the appropriate linkage in the 2nd biological stage. of anoxic reactors into the flow system of the 2nd stage, intensive mixing with the biological sludge and providing the required recirculation.